De doelstellingen van de CRMA zijn drieledig:

- Zorg voor een gestage levering van essentiële grondstoffen voor de industrie van de Europese Unie (EU).

- Versterken de veerkracht van de supply chain.

- Moedig diversificatie van sourcing aan en afnemende afhankelijkheden.

Deze doelen zijn bedoeld om het volgende te bereiken:

- Bescherming van het concurrentievermogen van de EU -industrie door de toegang tot grondstoffen te vergemakkelijken die cruciaal zijn voor het bevorderen van groene technologie.

- Verminder de gevoeligheid voor verstoringen in de supply chain, zoals die zijn getuige tijdens de Covid-19 pandemische en natuurlijke calamiteiten.

- Beperk de dreiging van economische dwang, met name uit China.

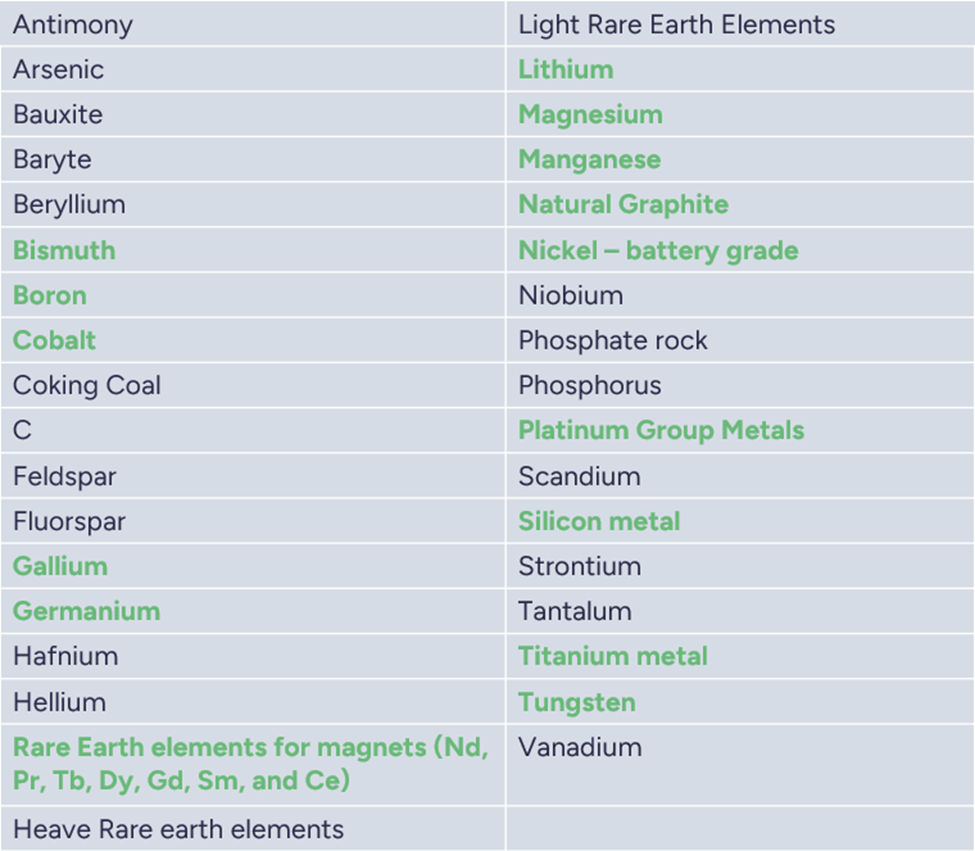

Kritische grondstoffen (CRM) zijn gecategoriseerd op basis van de volgende criteria:

- Economische betekenis voor de bredere EU -economie.

- Beoordeling van leveringsrisico's.

Strategische grondstoffen (SRM), een subset van kritieke grondstoffen (CRM's), worden gedefinieerd door criteria, waaronder:

- Belang bij het bevorderen van de groene en digitale overgangen.

- Relevantie voor verdedigings- en ruimtetoepassingen.

- Hoog geprojecteerde toekomstige vraag ten opzichte van de huidige wereldwijde productie.

De inventaris van kritieke grondstoffen (CRM's) en strategische grondstoffen (SRMS) die relevant zijn voor groene technologieën zal onderworpen zijn aan periodieke herzieningen door de Europese Commissie:

Referentie: algemene methode om het gebruik van kritieke grondstoffen in energiegerelateerde producten te verklaren

Verplichte vereisten voor bedrijven

- Bedrijven moeten niet afhankelijk zijn van een enkel derde land voor meer dan 65% van de levering van strategische grondstof, onbewerkte en in elk geval van verwerking

- Audit van de supply chain: grote bedrijven met een subgroep van kritieke grondstoffen (SRM's) in strategische technologieën moeten om de twee jaar verplichte supply chain-audits ondergaan. Voorbeelden van dergelijke technologieën omvatten, maar zijn niet beperkt tot:

- Energieopslag en elektrische mobiliteitsbatterijen.

- Apparatuur voor waterstofproductie en -gebruik.

- Apparatuur geassocieerd met hernieuwbare energieopwekking.

- Tractiemotoren.

- Warmpompen.

- Gegevensoverdracht en opslagsystemen.

- Mobiele elektronische apparaten.

- Apparatuur gerelateerd aan additieve productie.

- Robotica.

- Drones.

- Satellieten.

- Geavanceerde chips.

- De audit moet een stresstest op SRM -toeleveringsketens omvatten om hun kwetsbaarheid voor verstoringen te beoordelen door de potentiële impact van verschillende scenario's te evalueren. Deze evaluatie moet overwegen:

- Locaties van SRM -extractie, verwerking of recycling.

- Capaciteiten van economische exploitanten langs de waardeketen en marktstructuur.

- Factoren die de levering beïnvloeden, zoals geopolitieke omstandigheden, logistiek, energievoorziening, personeelsbestand of natuurrampen.

- Beschikbaarheid van alternatieve aanbodbronnen en vervangende materialen.

- Identificatie van gebruikers van de relevante SRM in de waardeketen, met bijzondere aandacht voor technologieën die relevant zijn voor de groene en digitale overgangen, defensie en ruimtevaartindustrie.

- Bedrijven moeten informatie verzamelen over de aanwezigheid van kritieke grondstoffen in hun producten om hun verplichtingen te kunnen nakomen.

- Ten minste 10% van wat de EU elk jaar gebruikt, zou van de EU zelf moeten komen.

Ten minste 40% van de jaarlijkse behoeften van de EU moet binnen de EU worden verwerkt.

Ten minste 15% van het jaarlijkse verbruik van de EU moet worden voldaan door middel van recyclingmaterialen.

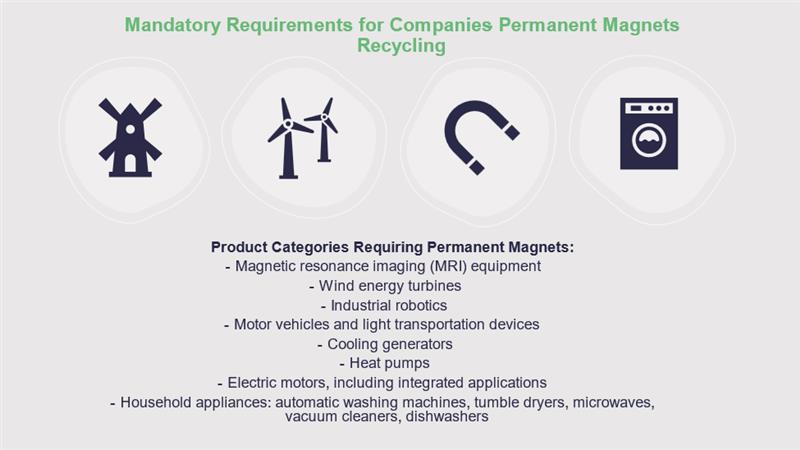

Scope -producten voor speciale vereisten van permanente magneten:

De lijst met relevante producten omvat:

- Magnetische resonantie beeldvormingsapparaten

- Windenergiegeneratoren.

- Industriële robots

- Motorvoertuigen

- Lichte transportmiddelen

- Koelgenerators

- Warmtepompen

- Elektrische motoren, inclusief die geïntegreerd in andere producten zoals automatische wasmachines, tumble driers, magnetrons, stofzuigers en vaatwassers.

Speciale vereisten van permanente magneten:

- Specificaties voor bedrijven die producten introduceren met permanente magneten op de markt.

- Producten moeten prominent een duurzaam label weergeven dat aangeeft:

- Of het product permanente magneten bevat.

- Als magneten aanwezig zijn, specificeert u hun type (bijv. Neodymium-ijzer-boor, samarium-cobalt, aluminium-nickel-cobalt, ferriet).

- Producten moeten een datacrager omvatten met een unieke identificatie:

- COMPANY CONTACT Gegevens.

- Gewicht, locatie en chemische samenstelling van elke permanente magneet, inclusief coatings, lijmen en additieven.

- Instructies voor het lokaliseren en verwijderen van permanente magneten, inclusief gereedschap of technologieën vereist.

- Een vrijstelling wordt verleend voor producten waar magneten uitsluitend binnen ingebedde elektromotoren zijn, ter vervanging van gedetailleerde magneetspecifieke informatie.

- Producten met paspoorten met digitale product moeten vereiste informatie bevatten.

- Informatie moet betrekking hebben op het productmodel of, voor verschillende eenheden, tot specifieke batches of eenheden.

- Recyclers, marktbewakingsautoriteiten en douane moeten toegang krijgen tot deze informatie.

- Overgangsperioden:

- Drie jaar na de regulering.

- Vijf jaar na de regulering Enactment voor specifieke apparaten zoals magnetische resonantie beeldvormingsapparatuur, motorvoertuigen en lichte transportvoertuigen.

- Elektrische motoren, inclusief die geïntegreerd in andere producten zoals wasmachines, drogers, magnetrons, stofzuiger en vaatwassers.

- Onthullende gerecyclede inhoudsdetails openbaar maken

Bedrijven die producten introduceren met permanente magneten van meer dan 0,2 kg moeten het percentage gerecycled neodymium, dysprosium, praseodymium, terbium, boor, samarium, nikkel en kobalt bekendmaken. Deze informatie moet publiekelijk toegankelijk zijn.

Klanten moeten toegang tot deze informatie vóór aankoop of contract.

Deel met uw gemeenschap

Opmerkingen

Laat een reactie achter of stel een vraag